Blog

OUR LATEST NEWS

In our blog, we regularly report on interesting facts about KEB Automation, customer solutions and new products. Our news allows you to immerse yourself in interesting subjects and find out first-hand about current trends in the area of drive and automation technology.

Find out KEB Automation’s news quickly and easily. Subscribe to our RSS news and you will receive the latest announcements automatically and promptly – even if you haven’t opened the KEB website. All you need is an application or a program that can display RSS feeds: https://keb-automation.com/blog.recent.xml

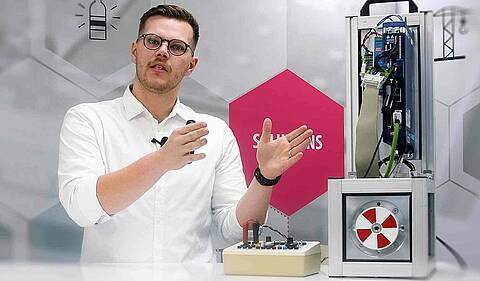

How to...: The Digital Outputs of the COMBIVERT F6/S6 Drives [GER with EN subtitles]

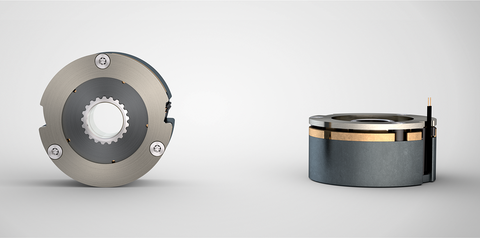

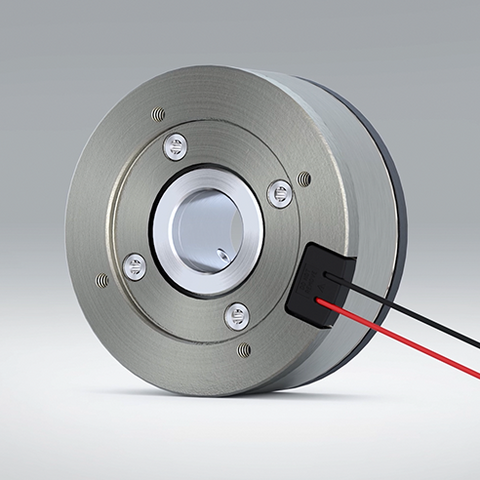

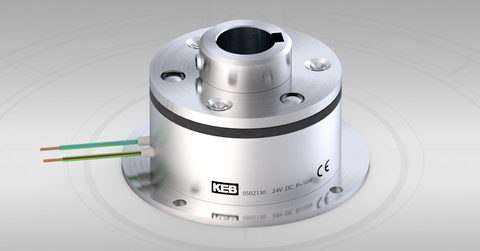

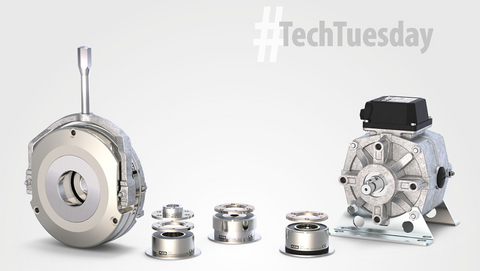

Safety first: What brakes have to perform in intralogistics [GER with EN subtitles]

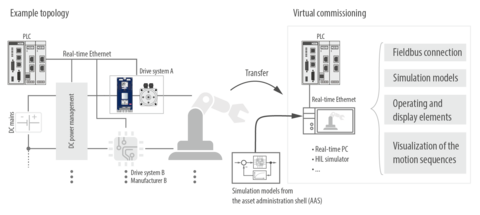

Simulation models – the “turbo” for commissioning

KEB Automation launches online service portal

New HMI management system HELIO presented

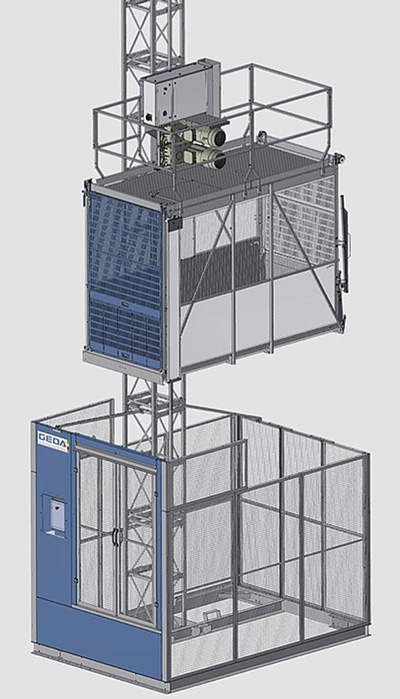

Commissioning time reduced by up to 90 percent

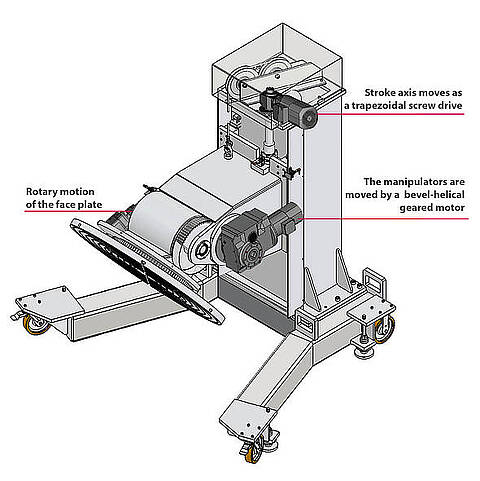

Material Handling: How to move and lift properly

Wind turbines

Brake innovations for your servo motor: more torque, less remanence [Language: GER]

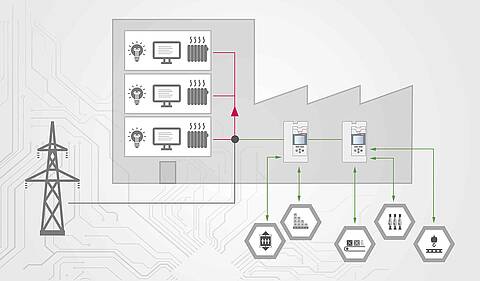

Saving in the DC network: How to reuse energy in the system [Language: GER]

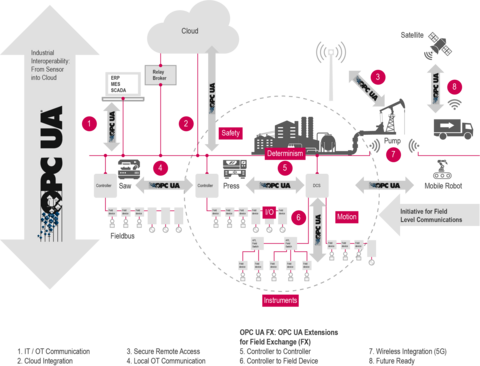

Not science fiction

TwinCat & Co.

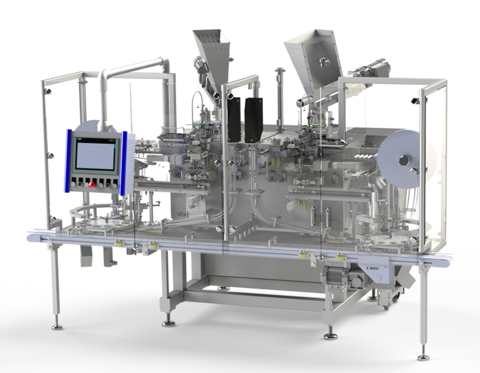

900 sachets per minute with KEB system solution

Everything under control in process technology

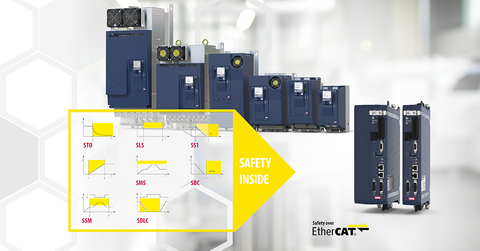

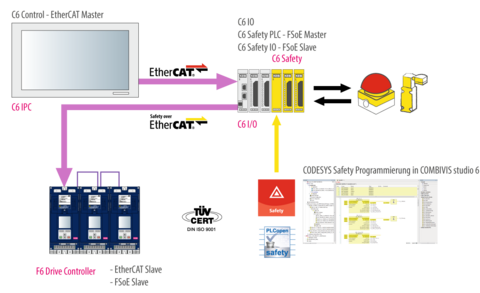

How safety gets into robots

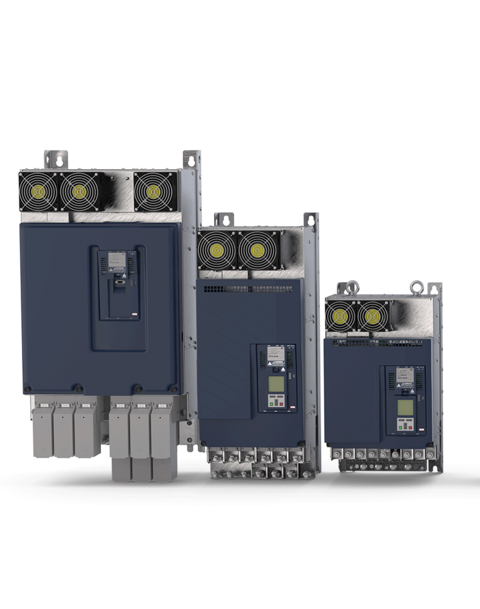

Drive controller for less heat loss

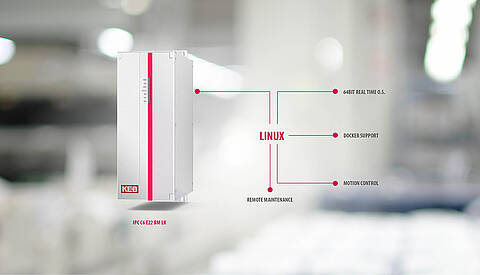

Product premiere: Embedded control C6 COMPACT 3

Servo Drives and Drive Controller

Lower rejects through optimised press

Increase the efficiency of your food and packaging machines [Language: GER]

Medical meets magnet technology

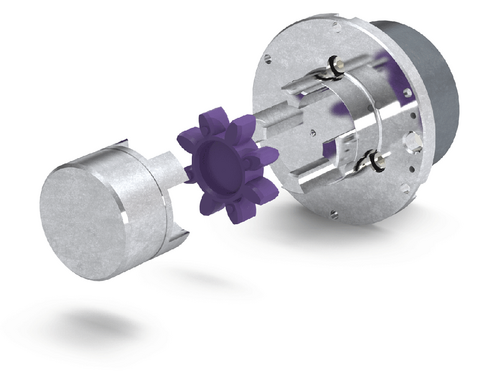

The clutch: air gap adjustment made easy

More than a repair: KEB renews warranty

We stay cool

Identifying problems before they occur

Recycling machines: Use under harsh conditions

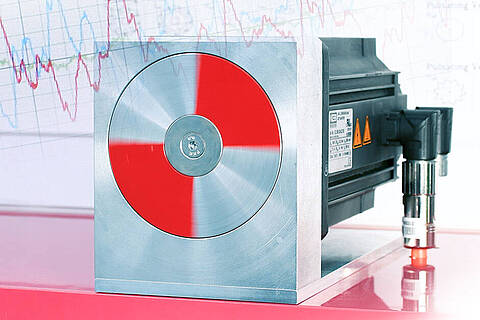

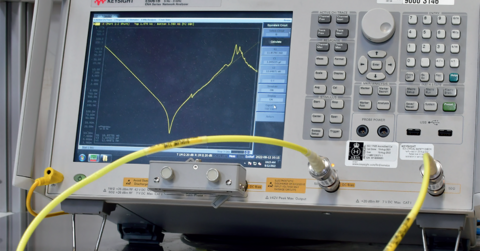

Future-proof speed evalutation

Safe speed evaluation

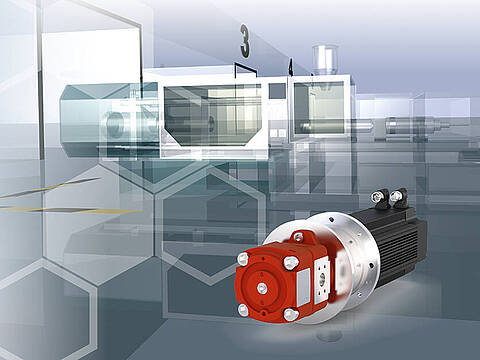

The Servo Pump

Lowest Speeds – High Torque

Via app and Bluetooth adapter in the drive controller

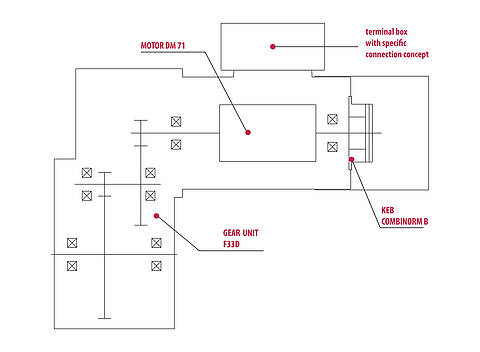

The motor and gear as you need it

Frequency inverter with extended power range

Automation – synchronized in every step

Recipe management made easy

A servo drive flies with Zeppelin

How AC/DC rocks your electric vehicle

Supply/Regeneration systems

Driving the Synchronous Reluctance Motor

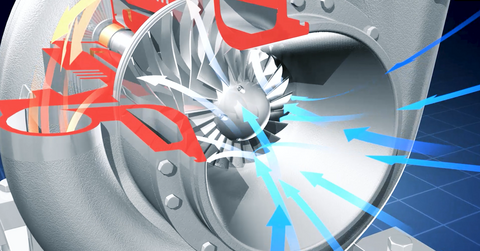

Ready for High-Power Wind Turbines

High performance: The future of wind turbines

Briefly explained

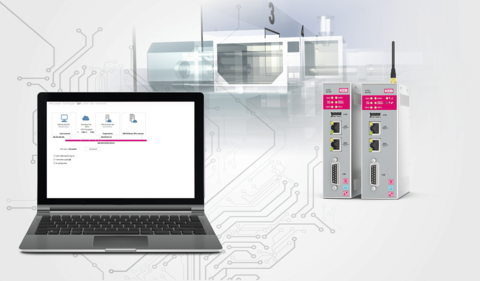

Remote maintenance with COMBIVIS connect

Ecodesign and drive controller

The Powerbox Eco

Via remote maintenance into the machine

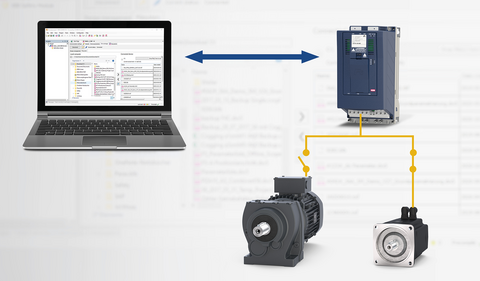

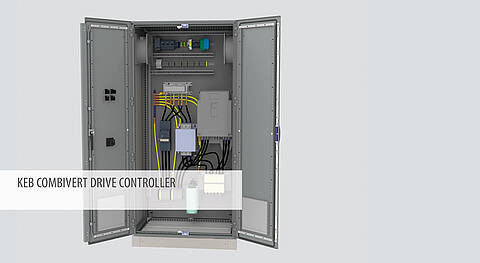

Starting up the drive system

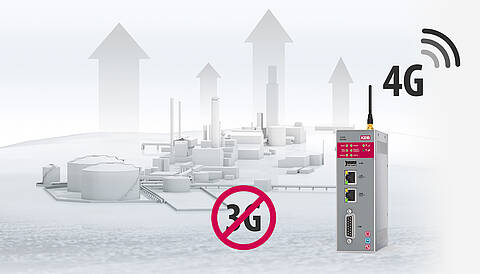

Bus retrofit as a sustainable solution

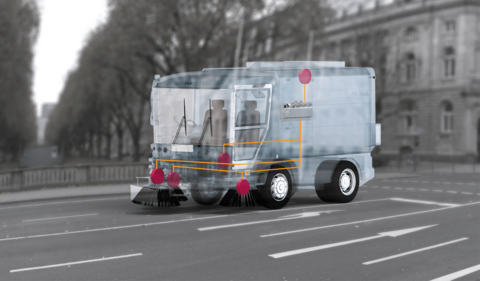

Electromobility in commercial vehicles

Application and Servo Drives

How to plan your Drive System energy-efficiently

The brake - Intelligent, energy-saving and bistable

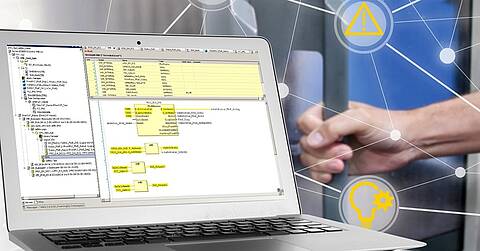

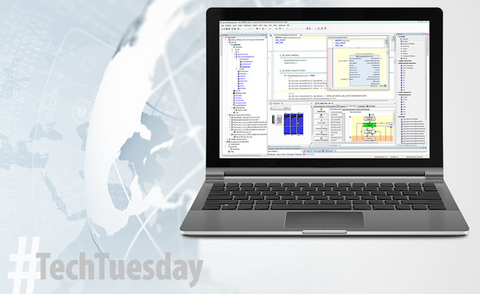

Best practise in programming with IEC 61131-3

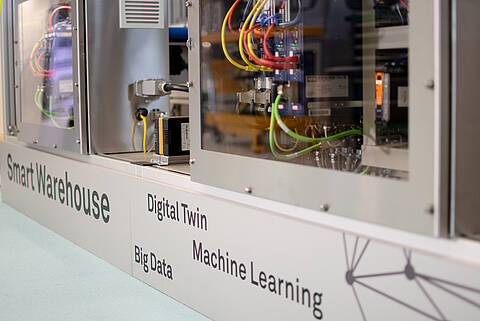

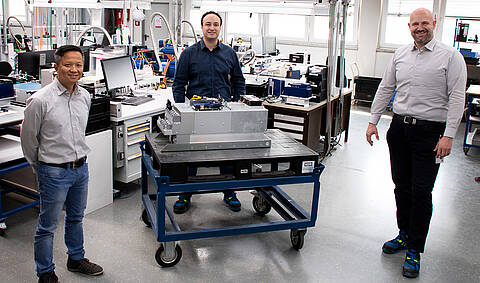

With digital twin into condition monitoring

The high-end CNC soulution in practice

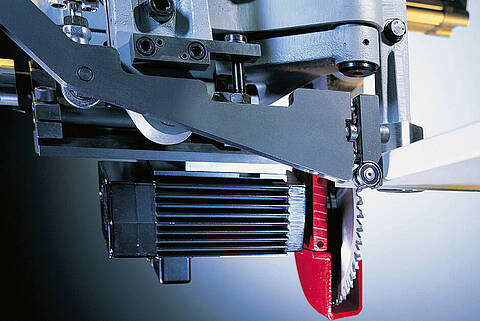

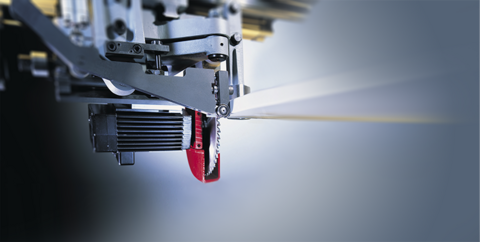

A brake shows teeth

This list contains no blog posts.