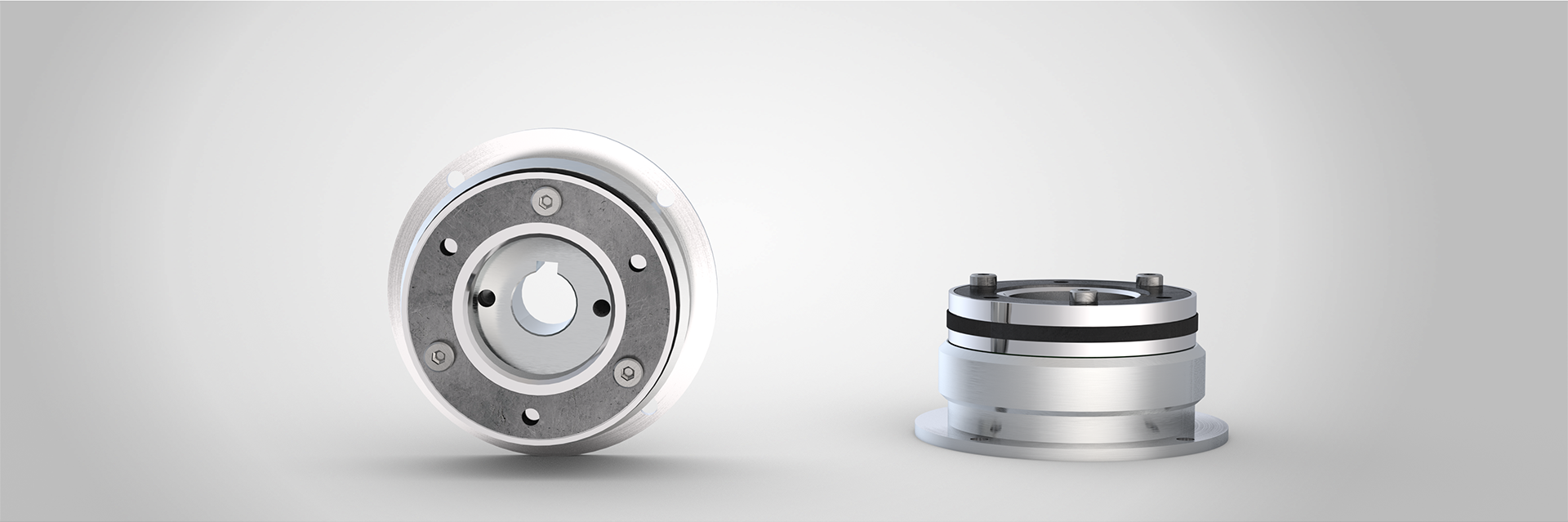

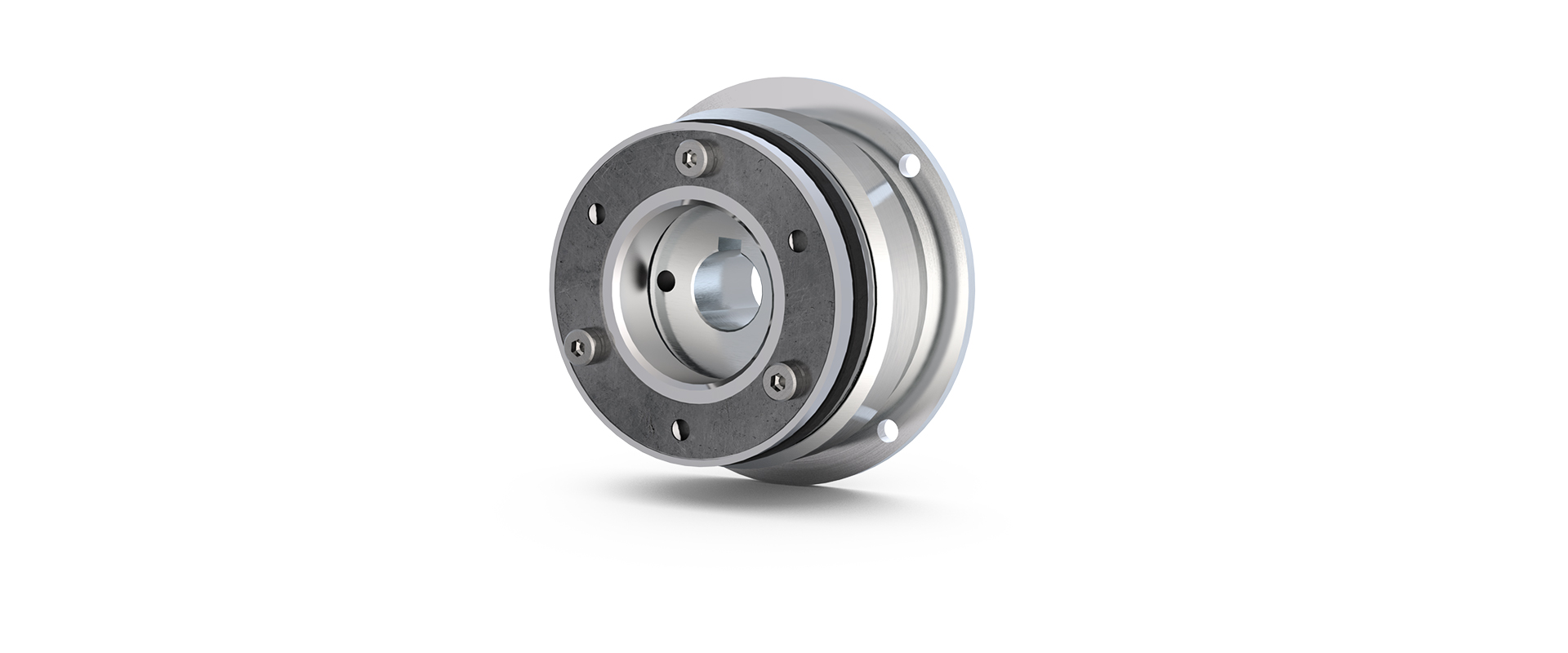

PERMANENT MAGNET CLUTCH

COMBIPERM PC

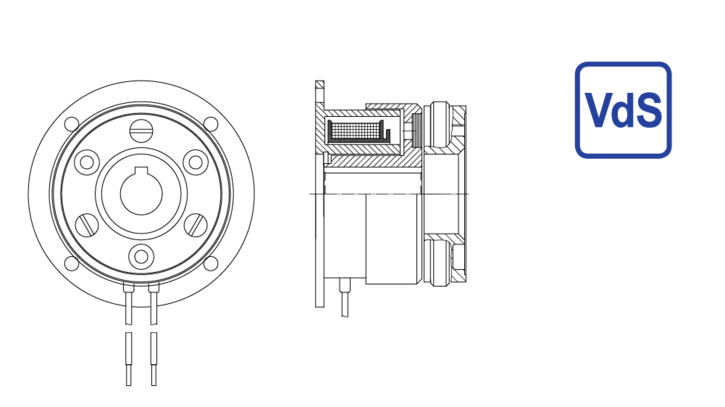

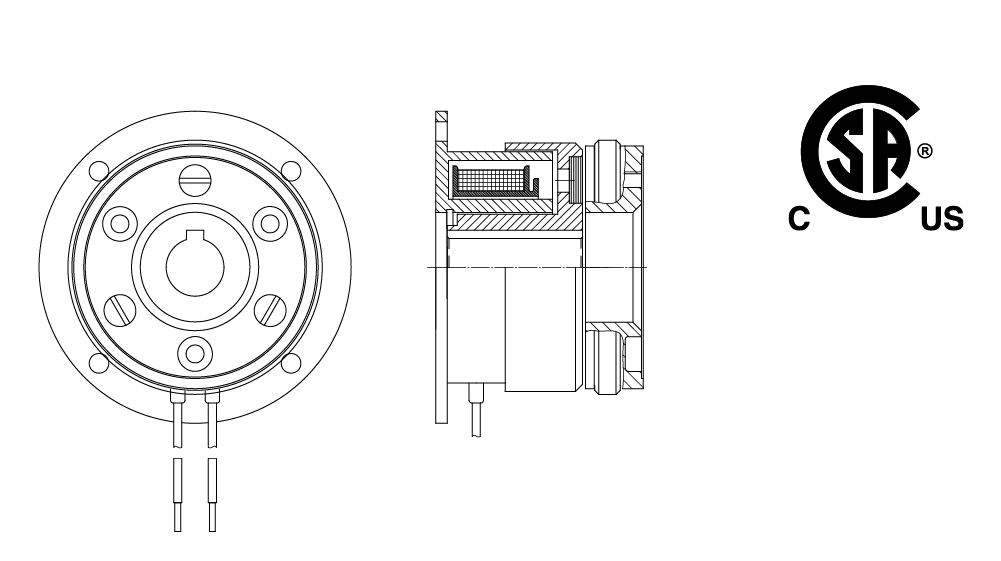

Our COMBIPERM PC is a permanent magnet clutch which uses frictional engagement to transmit torque in the de-energised state. This means that high torques can be reliably transmitted in small assembly spaces. The frictionally engaged connection opens when a voltage is applied, cancelling out the force action of the permanent magnets.

The permanent magnet clutch has a torque range of 6 Nm to 120 Nm.

Highlights

- 7 sizes

- Frictionally engaged torque transmission

- ISO class F in accordance with VDE 0580

- Designed for S1 operation or 100 % duty cycle

- Standard voltage 24V

Options

If the COMBIPERM PC standard flange does not fit the installation situation, both the bore hole pattern and the bearing seat recess of the standard flange can be adapted to the customer’s requirements.

If the application requires a modified voltage, a customised coil with the corresponding voltage can be realised in the internal production process.

If the assembly process of the brake has to be simplified, our products can be equipped with ready-to-connect cables with plugs, contacts or even wire end ferrules.

A factory certificate 2.1 according to DIN EN 10204 that the delivered products comply with the agreements at the time of order can be provided at the customer's request. This certificate is issued based on non-specific testing. Also, an acceptance test certificate 3.1 according to DIN EN 10204 can be issued at the customer's request. In this case, the confirmation is given with the results of specific tests, such as the torque test.

TECHNICAL DATA

| Size | Rated torque M2 [Nm] | Standard power [W] | Diameter [mm] | max. Rotor bore [mm] | max. Hub bore [mm] |

| 03* | 1.5 | 13 | 54 | 10 | 10 |

| 05* | 3 | 10 | 65 | 15 | 15 |

| 06 | 6 | 18 | 80 | 20 | 18 |

| 07 | 12 | 24 | 100 | 25 | 22 |

| 08 | 24 | 28 | 125 | 30 | 30 |

| 09 | 50 | 35 | 150 | 35 | 35 |

| 10 | 120 | 80 | 190 | 50 | 45 |

Standard voltage: 24 V | Special voltage: on request

In use in these areas of application

MEDICAL TECHNOLOGY

Precision, safety and repeatability are essential in medical technology. This requires solutions that are as reliably produced as the work in the healthcare industry demands. With know-how and established products, KEB has been meeting the high demands in medical technology for decades.

WOODWORKING MACHINERY

KEB’s variable-speed frequency inverters create the perfect basis for treating and processing the renewable and carbon-neutral raw material, wood – in complete safety.

E-MOBILITY

With innovative solutions, KEB enables the electronic operation of auxiliary systems in commercial vehicles and mobile machinery, thereby reducing emissions.

MATERIAL HANDLING

Whether warehouse logistics or cranes, speed and flexibility are essential in material handling. KEB ensures a smooth flow of goods and materials in this area.

PLASTICS MACHINERY

For extrusion and injection moulding technologies, we offer hardware and software solutions out of one hand that ensure a high level of availability and torque accuracy.

PACKAGING & FOOD PROCESSING

KEB provides the food processing and packaging industry with robust components that are suitable for use in harsh environments.